Jade Electronics Solutions Ltd as a very experienced new company, has a very stable organised structured beginning. It's experienced background, hold no limits to it's capability and with time will continue to grow to greater serve it's devoted customer base.

The Directors are definitely no stranger to rapid development coupled with growing customer demand and unwavering quality standards.

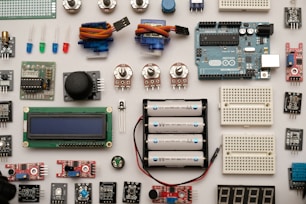

CAPABILITIES

OUR

PROCESS OF BUYING

SERVICE & PROCESS VIEWING

Viewing is optional but we are here to help you find the perfect place for your products. Depending on your needs, we will explain in simple detail every process. We will suggest services to perform and book you in if you'd like a viewing. And we understand that every customer is different, no matter the size or complexity of your product or business we are here to help. And the service will always be the same for every customer.

1

NEGOTIATING TERMS

We aim to get it right and be competitive in the market, so we don't just let you guess what service is required. We will guide you through our services and explain the options in detail. Once you've found the service level that you require and are ready to request a quotation. Place a request, we will contact the vendors and negotiate the best terms to suit your budget and needs.

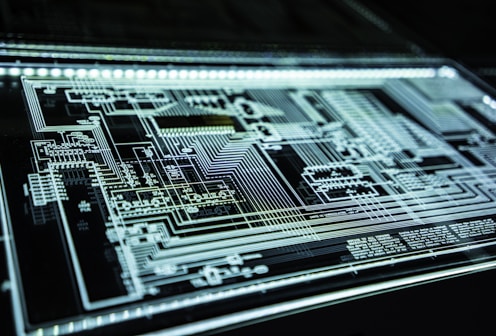

DESIGN REVIEW

We don't play around – that means that our IP is important to us and so is our customers IP. Once a contract is confirmed and confidential agreements are signed, we will onboard your product. Everything about the design could be reviewed but ultimately we want to save the customer money in reducing component cost and simplified manufacturing. But we always make sure that the customer is in control. To leave you with the confidence that your product manufacturing process is being looked after.

2

3

DESIGN ASSISTANCE

Whatever level of design capability you have we can offer assistance to make your design a reality.

Whether it is value engineering or something more complex like HV, MOD or Aerospace. We have professional knowledge in many software platforms and manufacturing techniques to assist you along the journey or design it all for you.

ON DEMAND SERVICE

Offering flexible services for your demand whether it be a rapid turn around to a target market or manufacturing overflow to accommodate an over capacity. We can offer a fully flexible service, rapid turn around PCB's, tooling and manufacture.

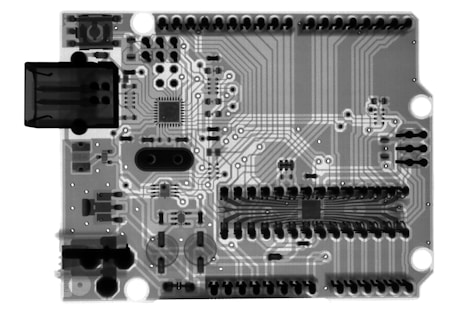

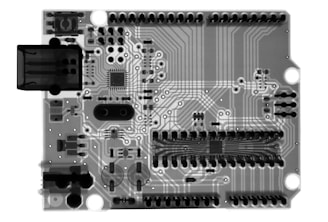

REVERSE ENGINEERING

Is your legacy product reaching the end of it's component lifecycle due to obsolescence or you haven't managed to retain the circuit diagrams for your design, we are here to help. With our in house expertise and our design partners we can perform your design changes to your requirement.

NPI MANAGEMENT

New product Introduction is performed for every new contract, batch sizes are of course selectable and we very familiar with First Article Inspection Reports. Project control, communication and organisation is always the focus of all manufacture regardless. We understand that NPI requires a further emphasis upon this control to manage all deadlines and milestones effectively.

From IPC lvl1 to lvl3, Mission or Life Critical we know the standards and practices required to manufacture your product. From standard practices, conformal coatings, to critical cleanliness we've got it covered, whatever your project.

Value Engineering

Reverse Engineering

Pre-manufacture Design Analysis

Design & Manufacture

Custom Metalworks

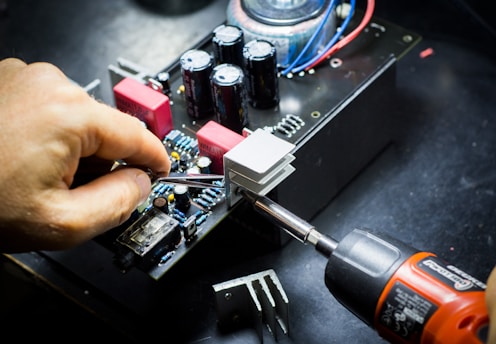

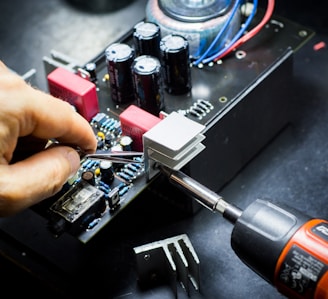

THROUGH HOLE ASSEMBLY

Often referred to as PTH or Conventional Assembly, we are familiar with all techniques for Leaded component manufacturing. Aerospace, MOD, IPC, odd form, clinches, press fit, thermal relief, stakings, maskings and coatings. HV assembly techniques, critically clean and so on, we know all the methods and measures to use to make your manufacturing solution.

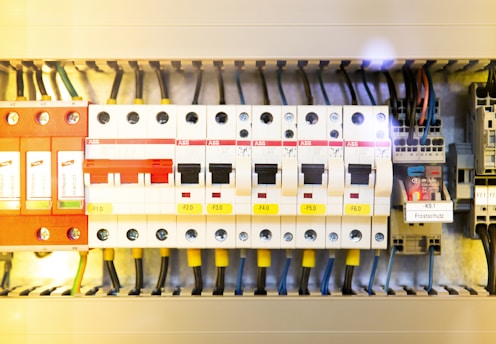

BOX BUILD

Box build, radius profiles and service loops, banding, shrinking, crimping and more all performed to the customers specification or we can assist by building to schematic using our skills and expertise in IPC and Aerospace manufacturing techniques to give you the approach that you desire.

CABLE ASSEMBLY

We are familiar with all types of cable assemblies from general to multicore, HV, Aerospace, MOD and so on. We can produce anything to documentation and ready to send to the customer for approval within a few days. We can also make cables on the fly or design them in. As desired we can also source from oversea sources to attain competitive prices to suite the customers requirements.

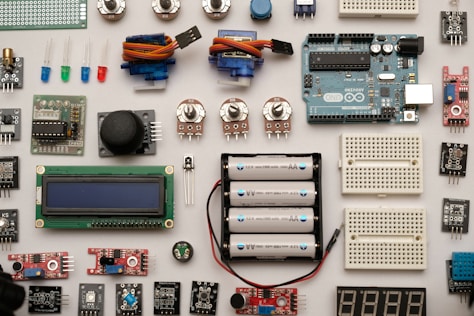

SURFACE MOUNT ASSEMBLY

Automated Surface mount assembly techniques to fit electronic components of many sizes from m0201 upwards can be easily performed by our professional team. The components will be fitted using expert manufacturing practices and with full controlled automation and inspection control methods. All of our assemblies not just surface mount are manually checked multiple times to ensure only the best quality to the customer.

On demand we can produce automated assembly Rapid prototypes and FAIR control with full manufacturing quality reports to assist with DFM changes.

PROGRAMMING & TEST

We can perform any test routines to specification and we can produce test/ performance logs per item at request. We are familiar with all types of in circuit test and all programming. We can produce manufacturing programming and test jigs either as defined, supplied or requested. We can produce anything to documentation and we can also make test routines on the fly or design them in to suite the customers requirements.

QUALITY REPORTING

FINAL ASSEMBLY

We understand that mechanical assembly isn't always just as simple as it looks. For the customer demand it's about using torque gauged electrical screwdrivers and tools. And using professional engineering knowledge for the correct form, fit and function of the final assembly.